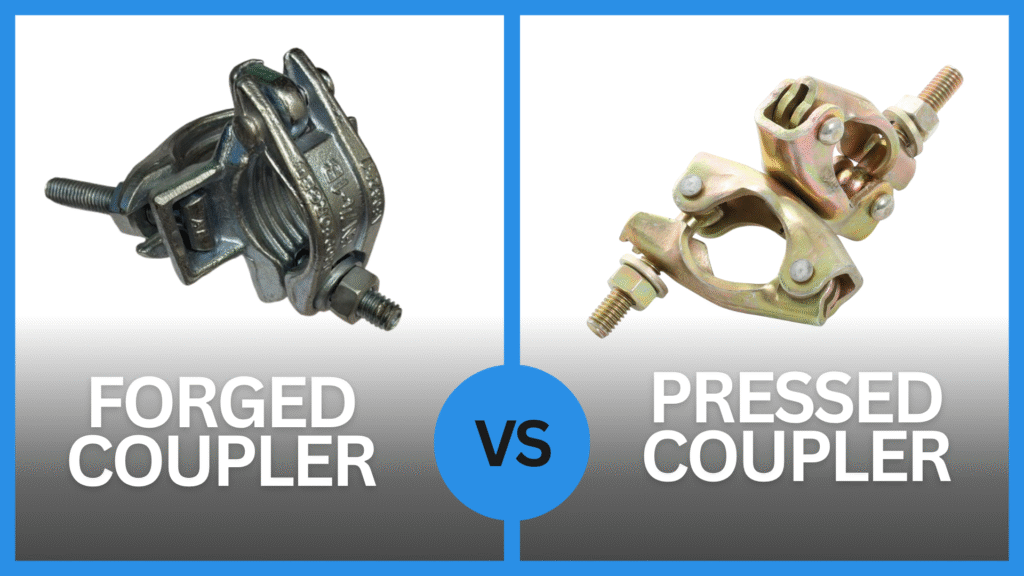

In the world of scaffolding, every component is a critical link in the chain of safety. Among these, couplers—the clamps that hold the tubes together—play one of the most vital roles. Choosing the wrong type can compromise the entire structure. let’s introduce forged vs pressed couplers,

When choosing between forged vs pressed couplers, contractor safety should be the primary consideration. This comprehensive guide examines the critical differences between these two scaffolding components and provides actionable insights for making the safest choice on your construction site.

Let’s break down the critical differences to ensure you make the right, and safe, choice for your construction site.

What is a Forged Coupler? (The Power of Pressure)

Forged Couplers, specifically Drop Forged Couplers, are manufactured by heating a single piece of high-strength steel until it’s malleable and then hammering or pressing it into a solid, dense die under immense pressure.

Think of it like a blacksmith shaping a sword: the process aligns the steel’s grain structure, creating a part that is incredibly strong, dense, and free from internal voids.

| Key Characteristics of Forged Couplers: |

| Manufacturing: Heated and shaped under high pressure (Drop Forging). |

| Material: Single piece of high-carbon steel. |

| Weight: Significantly heavier and denser. |

| Strength: Very high tensile strength and load-bearing capacity. |

| Standards: Typically conform to stringent standards like IS 2750 (India), BS EN 74 (Europe), and AS/NZS 1572 (Australia/New Zealand). |

| Common Types: Right-Angle Couplers, Swivel Couplers, Putlog Couplers |

.

What is a Pressed Coupler? (The Speed of Stamping)

Pressed Couplers (or Pressed Steel Couplers) are made from thinner sheets of mild steel that are cold-stamped or pressed into shape. They are often made from two halves that are spot-welded or riveted together.

Think of it like stamping a shape out of a sheet of paper: it’s a fast and cost-effective process, but the resulting product lacks the structural integrity of a forged component.

Key Characteristics of Pressed Couplers:

Manufacturing: Cold-formed from sheet metal (Stamping/Pressing).

Material : Two halves of thinner mild steel, often welded.

Weight: Lighter and less dense.

Strength: Lower tensile strength and load capacity.

Standards: Rarely meet high international safety standards; often used for light-duty or non-structural applications.

Common Types: Basic right-angle clamps for light-duty work.

| Feature Forged Coupler Pressed Coupler Manufacturing Process Heated and hammered into a die (Drop Forged) Cold-stamped from sheet metal Structural Integrity Single, solid piece with aligned grain — superior strength Two halves welded/riveted — weaker joints Strength & Load Capacity Very High — designed for heavy-duty scaffolding Low to Moderate — suitable for light-duty only Durability & Lifespan Extremely durable; withstands rough handling and long-term use Prone to bending, warping, and weld failure — shorter lifespan Safety & Compliance Complies with IS 2750, EN 74 — essential for commercial and industrial projects Often non-compliant with safety standards — a significant risk Cost Higher initial investment, but better long-term value Very low initial cost Best For Heavy-duty scaffolding: high-rises, industrial, and formwork projects Light-duty use: small domestic repairs, non-structural supports, painting .When choosing between forged vs pressed couplers, contractor safety should be the primary consideration. This comprehensive guide examines the critical differences between these two scaffolding components and provides actionable insights for making the safest choice on your construction site. |

The Critical Takeaway: Why Forged is Almost Always the Answer

While the low upfront cost of pressed couplers is tempting, it’s a dangerous false economy. Here’s why forged couplers are the unequivocal choice for professional construction:

Safety comparison of forged vs pressed couplers

Total Cost of Ownership (TCO): A forged coupler can last for decades and hundreds of projects. A pressed coupler may bend or break on its first use, needing constant replacement. The long-term value and reliability of forged couplers far outweigh their initial price.

Project Compliance: Any reputable project manager, safety officer, or client will demand scaffolding that meets national safety standards like IS 2750. Using non-compliant pressed couplers can halt your project and lead to legal and financial repercussions.

Conclusion: Invest in Safety, Choose Forged

The choice between forged and pressed couplers is simple when you prioritize safety and professionalism.

For any commercial, industrial, or high-risk project: Your only choice is drop-forged couplers from a reputable manufacturer that provides test certificates.

Pressed couplers should be viewed with extreme caution and relegated only to the most basic, non-structural, and temporary DIY tasks.

Don’t let the weakest link be the clamp you chose to save a few rupees. When lives are on the line, always build on the forged foundation of safety.Understanding the differences between forged vs pressed couplers can significantly impact job site safety and project success. Always prioritize certified components that meet ASTM international standards for maximum protection.

Looking for reliable, IS-certified forged scaffolding couplers? Browse our range of premium couplers, engineered for strength and built to last. Contact our team today for a quote .

Follow us on instagram https://www.instagram.com/amcoexports/?igsh=MWphOXE1dW5icXY2aw%3D%3D#