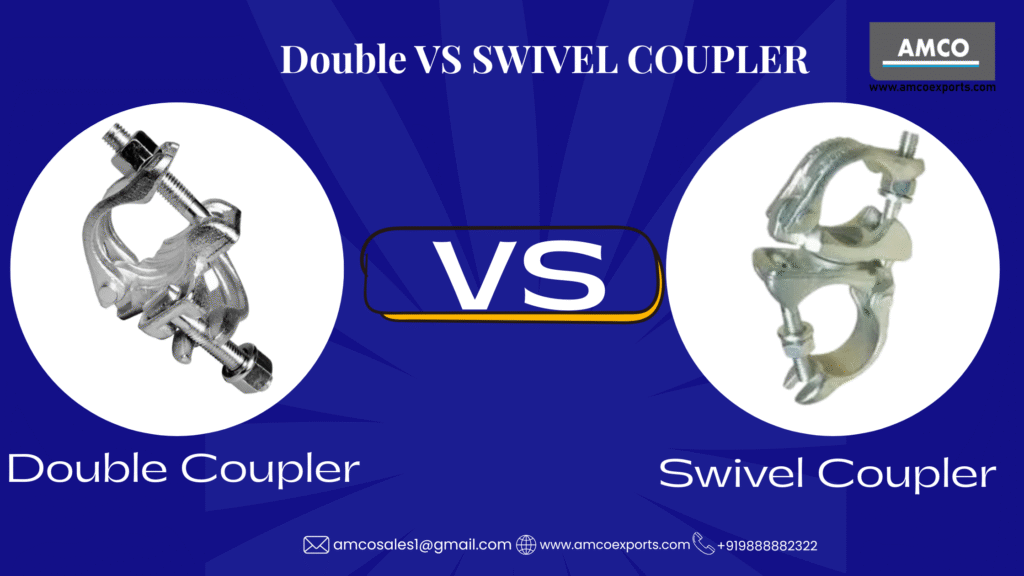

Double vs Swivel Coupler is one of the most searched comparisons by contractors when selecting scaffolding fittings. Although both couplers look similar, they serve very different purposes on site — one forms the main structure, while the other provides diagonal support.

Choosing the wrong coupler often leads to loose joints, alignment issues, and repeated replacement. That’s why understanding their difference, size, and price before ordering is critical for safe and efficient scaffolding.

Most contractors ask the same questions:

Which one is stronger?

Which one handles load better?

What size should I buy?

And why does swivel coupler price differ from double coupler price?

Let’s clear it up.

This guide explains Double Coupler vs Swivel Coupler: Difference & Use in simple terms, so you can order correctly, avoid site delays, and keep your scaffolding safe.

What Is a Double Coupler in Scaffolding?

A double coupler (also called right angle coupler) connects two scaffold tubes at a fixed 90-degree angle.

It forms the main skeleton of scaffolding structures by joining vertical standards with horizontal ledgers.

Common Double Coupler Uses

- Main scaffolding framework

- Vertical to horizontal connections

- Load-bearing joints

- Square and rectangular layouts

Why Contractors Prefer Double Coupler Scaffolding

Because it creates rigid joints. Once tightened, there is no movement. This makes double coupler scaffolding ideal for primary structural support.

In simple words:

👉 Double couplers build the structure.

What Is a Swivel Coupler in Scaffolding?

A swivel coupler connects two scaffold tubes at any angle. Its rotating design allows flexibility where straight connections are not possible.

Common Swivel Coupler Uses

- Diagonal bracing

- Irregular layouts

- Sloped surfaces

- Extra side support

Why Swivel Coupler Scaffolding Matters

Swivel couplers absorb sideways forces and vibration. They don’t carry main vertical load, but they prevent wobbling and improve overall stability.

Simply put:

👉 Swivel couplers protect the structure.

Double Coupler vs Swivel Coupler: Key Differences

| Feature | Double Coupler | Swivel Coupler |

|---|---|---|

| Connection | Fixed 90° | Any angle |

| Movement | Rigid | Rotational |

| Primary Role | Main framework | Diagonal bracing |

| Load Handling | High | Medium |

| Flexibility | Low | High |

| Typical Use | Standards + ledgers | Cross bracing |

This is why professional scaffolding always uses both together.

Double Coupler vs Swivel Coupler Size (Standard)

Most scaffolding couplers in India follow:

- 48.3mm OD pipe size (standard scaffold tube)

- Bolt size usually M12 or M14 depending on model

At AMCO Exports, both double coupler scaffolding and swivel coupler scaffolding are manufactured to match standard 48.3mm pipes for perfect fit.

Double Coupler vs Swivel Coupler Price (What Affects Cost?)

Contractors often compare swivel coupler price and double coupler price, but here’s what really controls cost:

✅ Weight of coupler

✅ Forged vs casted material

✅ Bolt quality

✅ Surface finish (self / painted / galvanized)

✅ Packing method

Swivel coupler price is usually slightly higher because of its rotating mechanism.

But remember — cheaper couplers often mean:

❌ loose bolts

❌ cracking

❌ bending under load

❌ repeated replacement

That costs more in the long run.

Which Coupler Should You Use?

Choose double couplers when:

- Building main scaffold frame

- Connecting vertical and horizontal pipes

- Load-bearing is required

Choose swivel couplers when:

- Adding diagonal bracing

- Working on uneven structures

- Extra lateral strength is needed

Best practice: use both on every proper scaffolding system.

Why Contractors Choose AMCO Exports

At AMCO Exports, scaffolding couplers are manufactured with:

- Accurate pipe fit

- Consistent weight

- Strong bolt tightening

- Clean threading

- Export-grade packing

Our double coupler scaffolding and swivel coupler scaffolding are supplied to contractors, builders, and infrastructure projects across India.

Conclusion

Understanding Double Coupler vs Swivel Coupler: Difference & Use helps you avoid wrong purchases, site delays, and safety risks.

Double couplers create strength.

Swivel couplers add stability.

Together, they form a safe scaffolding system.

For reliable scaffolding couplers manufactured in India — connect with AMCO Exports today.

📞 +91 98888 82322

📧 amcosales1@gmail.com

🌐 www.amcoexports.com

Share your requirement — size, quantity, and location — quotation is provided quickly.

Follow AMCO Exports

Instagram: https://www.instagram.com/amcoexports

LinkedIn: https://www.linkedin.com/in/amcoexports/

Frequently Asked Questions – Double Coupler vs Swivel Coupler

What is the main difference between double coupler and swivel coupler?

The double coupler connects scaffolding pipes at a fixed 90° angle for main structural support, while the swivel coupler connects pipes at any angle and is mainly used for diagonal bracing.

Which coupler is stronger for scaffolding?

Double couplers handle higher loads and are used in the main framework. Swivel couplers provide lateral stability but are not primary load-bearing components.

What is the standard size of scaffolding couplers?

Most scaffolding couplers are designed to fit 48.3mm OD scaffold tubes, which is the standard size used on construction sites.

Why is swivel coupler price usually higher than double coupler?

Swivel couplers have rotating mechanisms and additional machining, which increases manufacturing cost compared to fixed double couplers.

Can swivel couplers replace double couplers?

No. Swivel couplers are used for support and bracing. Double couplers are required for building the main scaffold structure.

Where can I buy quality double and swivel couplers in bulk?

You can source heavy-duty scaffolding couplers directly from AMCO Exports. For bulk orders, call +91 98888 82322 or email amcosales1@gmail.com.