Steel truss fabrication depends heavily on safe access, accurate alignment, and load-stable working platforms. That’s why working with an industrial scaffolding supplier for truss manufacturing and reliable formwork accessories for fabrication is no longer optional – it’s a core production requirement.

At AMCO Exports, we support fabrication yards, EPC contractors, and industrial builders as an industrial scaffolding supplier, providing access systems and structural accessories that power truss assembly floors, welding platforms, inspection bays, and installation staging areas across India.

Let’s walk through how the right scaffolding setup directly impacts fabrication efficiency.

- Why Scaffolding Is Needed in Truss Fabrication

- Common Challenges in Truss Manufacturing Units

- Scaffolding Accessories Used in Fabrication Floors

- Case Study: Truss Fabrication Yard in North India

- Buying Tips for Scaffolding & Formwork Accessories

- Why Choose AMCO Exports

- Frequently Asked Questions

- Get Material Supply Support

Why an Industrial Scaffolding Supplier Is Needed in Truss Fabrication

Truss manufacturing involves elevated work at multiple stages — from positioning steel members to welding joints and final inspection. Ground-level access alone cannot support long-span fabrication.

Professional scaffolding for truss manufacturing provides:

- Safe access to elevated joints

- Level platforms for alignment

- Stable load paths during assembly

- Faster movement of manpower and tools

Without proper scaffolding, fabrication slows down, safety risks increase, and dimensional accuracy suffers.

This is where high-quality formwork accessories for fabrication and modular scaffold systems become essential.

Common Challenges in Truss Manufacturing Units

Most fabrication yards face similar operational issues:

Height Access

Large trusses require access at varying elevations. Temporary ladders or improvised supports create unsafe conditions.

Alignment & Level Control

Truss accuracy depends on adjustable support points. Fixed staging rarely offers the precision needed during assembly.

Load Handling

Steel members impose point loads that must be safely transferred through scaffold systems.

Worker Safety

Open fabrication floors require rigid couplers, guardrails, and stable platforms to reduce fall risk.

A reliable industrial scaffolding supplier helps solve these challenges with engineered accessories.

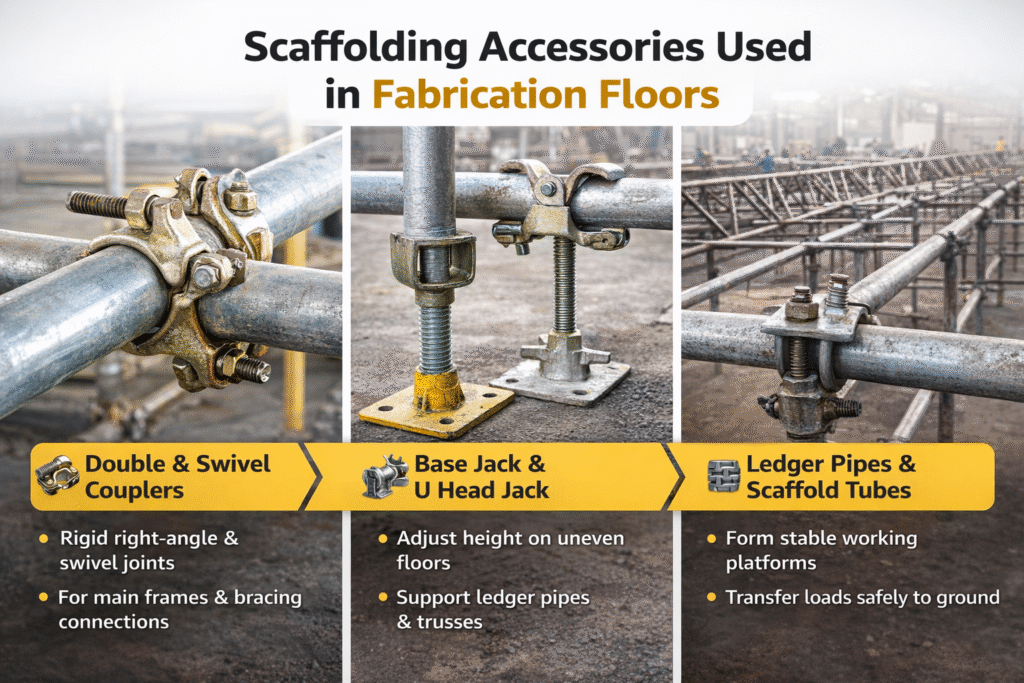

Scaffolding Accessories Used in Fabrication Floors

Here are the core components commonly supplied by AMCO Exports to truss manufacturing units:

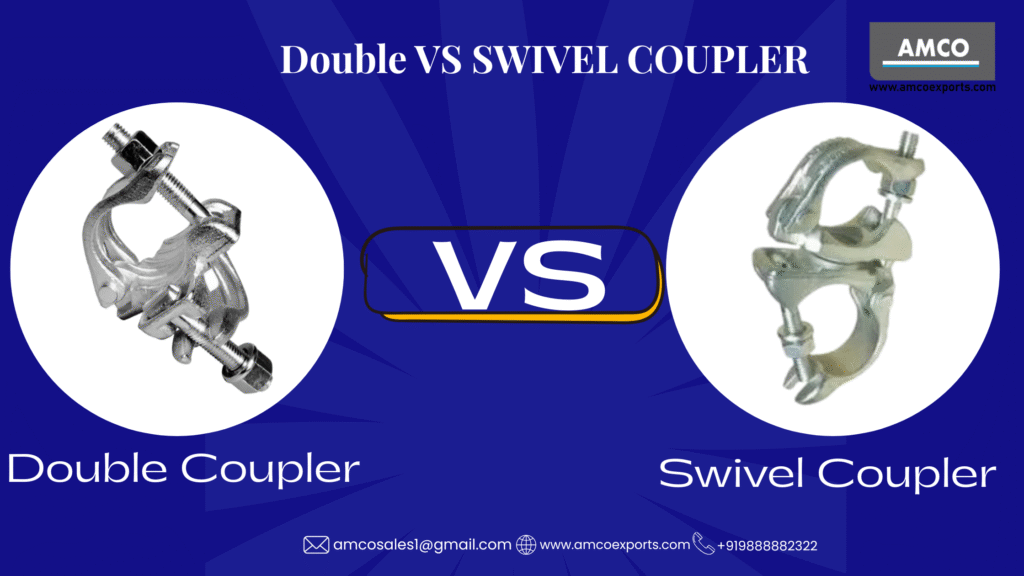

🔩 Double & Swivel Couplers

Double couplers create rigid right-angle joints for main frames.

Swivel couplers allow angled connections for diagonal bracing.

Together, they provide both strength and flexibility across fabrication platforms.

⚙️ Base Jack & U Head Jack

Base jacks adjust height on uneven yard floors.

U head jacks support ledger pipes or steel members during positioning.

They are critical for maintaining level platforms during truss assembly.

🧱 Ledger Pipes & Scaffold Tubes

Ledger pipes form the horizontal working levels, while vertical standards carry loads to the ground.

These components create the structural backbone of scaffolding for truss manufacturing.

🪛 Tie Rods (Temporary Support)

Tie rods are often used for temporary positioning, alignment holding, and light structural restraint during fabrication.

They play an important role in stabilizing formwork and access frames.

🧩 Waller Plates

Waller plates distribute loads from tie rods across larger surface areas and help maintain alignment in temporary formwork and support structures.

In fabrication environments, waller plates improve stability where localized loads occur, especially near base frames and staging zones.

Quick Comparison: Couplers vs Jacks vs Tie Rods

| Component | Primary Role | Typical Use in Fabrication |

|---|---|---|

| Couplers (Double & Swivel) | Pipe connection & bracing | Frame building, diagonal support, platform rigidity |

| Base Jack & U Head Jack | Height adjustment & load leveling | Uneven floors, steel member positioning, platform alignment |

| Tie Rod + Waller Plate | Temporary restraint & alignment | Formwork holding, staging stability, fabrication support |

Products Supplied for Truss Fabrication Floors

- Double Couplers & Swivel Couplers

- Adjustable Base Jack & U Head Jack

- Scaffold Pipes & Ledger Pipes

- Tie Rod System

- Waller Plates

- Formwork Accessories & Hardware

Case Study: Truss Fabrication Yard in North India

A large steel fabrication unit in North India approached AMCO Exports while expanding its truss production line for warehouse roofing projects.

Project Challenge

- Multiple long-span trusses under fabrication simultaneously

- Uneven yard flooring

- Requirement for adjustable access platforms

- Tight production deadlines

AMCO Exports Supply Scope

We supplied:

- Scaffold pipes and ledgers

- Double and swivel couplers

- Adjustable base jacks and U head jacks

- Tie rods and hardware fittings

Result

Within two weeks:

- Fabrication floors were operational

- Alignment time reduced significantly

- Safer access provided to welding teams

- Faster truss turnover achieved

The client continues to source formwork accessories for fabrication from AMCO Exports for ongoing projects.

This is exactly how a dependable industrial scaffolding supplier adds value beyond materials.

Buying Tips for Truss Fabrication Scaffolding

Before sourcing accessories, keep these points in mind:

Load Rating

Always confirm working load capacities of jacks, couplers, and pipes.

Coupler Strength

Use heavy-duty forged or pressed couplers with clean threads and proper galvanization.

Adjustability

Fabrication floors change constantly. Adjustable jacks save rework.

Packing Quality

Poor packing damages threads and bends pipes. Industrial supply needs proper bundling.

Dimensional Consistency

Uniform sizing speeds up assembly and improves alignment accuracy.

Choosing the right scaffolding for truss manufacturing starts with choosing the right supplier.

Why Choose AMCO Exports as Your Industrial Scaffolding Supplier

AMCO Exports is not a contractor – we are a dedicated industrial scaffolding supplier supporting fabrication yards, EPC companies, and infrastructure developers.

We supply:

- Scaffold pipes, ledgers, and standards

- Double & swivel couplers

- Base jacks and U head jacks

- Tie rods and formwork accessories

- Nuts, bolts, and structural fittings

Our materials are engineered for load performance, repeat usage, and long-term site durability across fabrication environments.

As an industrial scaffolding supplier, AMCO Exports focuses on fabrication-grade access systems built for load performance and repeat industrial use.

Get Material Supply Support :industrial scaffolding supplier

If you’re searching for:

- Scaffolding for truss manufacturing

- Formwork accessories for fabrication

- A reliable industrial scaffolding supplier

AMCO Exports is ready to support your project.

📞 Call: +91 98888 82322

🌐 www.amcoexports.com

Share your fabrication layout and material requirements — our team will help you plan the right supply.

Stay connected for product updates and project insights:

Instagram:

https://www.instagram.com/amcoexports/

LinkedIn:

https://www.linkedin.com/in/amcoexports/

Frequently Asked Questions

Q1. Do you supply scaffolding for fabrication yards only?

We supply scaffolding and accessories to truss manufacturers, EPC contractors, industrial plants, and infrastructure projects across India.

Q2. Are your couplers suitable for heavy steel fabrication?

Yes. Our double and swivel couplers are engineered for industrial load conditions and demanding fabrication environments.

Q3. Can AMCO Exports support bulk orders?

Yes. AMCO Exports regularly handles bulk dispatches for fabrication units, EPC projects, and industrial sites nationwide.

Q4. Do you provide installation services?

No. AMCO Exports supplies materials only. Installation and execution are carried out by specialist scaffolding contractors.

Q5. How do I get pricing?

Simply contact our sales team with your required quantities and project details for a fast quotation.