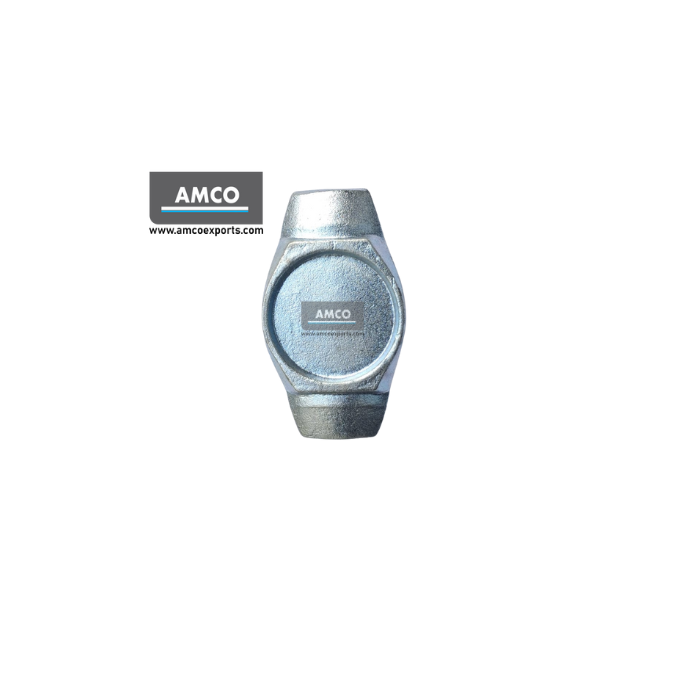

Ledger Blade Scaffolding – Drop Forged Cuplock Ledger Blade Manufacturer & Price

The Ledger Blade Scaffolding component is a critical locking element used in Cuplock scaffolding systems. Fixed at the end of horizontal ledgers, the blade locks securely into the cup joint of the vertical standard. As a result, it creates a rigid, load-stable connection that supports safe working platforms in construction and formwork projects.

AMCO Exports manufactures hot drop forged ledger blades designed for high impact resistance, precise fitment, and long service life. Because these blades handle repeated loading and rough site handling, contractors prefer forged blades over casted or fabricated alternatives.

Cuplock Ledger Blade Sizes & Weight Options

To match different structural and budget requirements, we supply ledger blades in multiple weight variants:

| Ledger Blade Weight | Typical Use |

|---|---|

| 150 g | Light-duty scaffolding |

| 160 g | Standard building work |

| 170 g | Balanced strength applications |

| 200 g | Medium-heavy construction |

| 250 g | Heavy-duty & industrial projects |

Heavier ledger blade sizes offer higher impact resistance, while lighter options support cost-effective standard construction.

Drop Forged Ledger Blade Construction

Unlike cast components, we manufacture each ledger blade using a hot drop forging process. This method improves grain flow and structural integrity. Therefore, the blade resists cracking, bending, and deformation even under repeated load cycles.

Key forging advantages include:

- High tensile and shear strength

- Accurate and consistent profile

- Tight locking inside Cuplock cups

- Long-term performance on demanding sites

Because of this process, forged ledger blades outperform fabricated and casted alternatives in both durability and safety.

Key Benefits of Ledger Blade

- Ensures strong horizontal connections in Cuplock systems

- Supports even load distribution across scaffolding bays

- Available with or without hole options

- Galvanized or coated finish for corrosion resistance

- Suitable for repeated erection and dismantling

As a result, contractors achieve faster assembly, safer platforms, and lower replacement costs.

Where and Why Ledger Blades Are Used

In practice, ledger blades play a vital role in:

- Connecting horizontal ledgers to vertical standards

- Maintaining rigid scaffolding geometry

- Supporting platform decking and access systems

- Construction, industrial maintenance, and infrastructure work

Because the blade locks directly into the cup joint, it prevents uplift, rotation, and movement during active site operations.

Ledger Blade Price & Bulk Supply

The ledger blade price depends on:

- Weight selection (150g–250g)

- Quantity required

- Finish (self / galvanized)

- Domestic or export packaging

For this reason, most buyers request pricing based on project volume and application type.

AMCO Exports supplies ledger blades directly from manufacturing, and we also support bulk orders, export shipments, and custom specifications.

Why Choose AMCO Exports

With decades of manufacturing experience, AMCO Exports is a trusted Drop Forged Ledger Blade Manufacturer in India. We maintain strict quality control across forging, finishing, and packing stages. Consequently, contractors and exporters rely on our ledger blades for consistent strength, accurate fit, and dependable site performance.

Customization in weight, finish, and batch quantity is also available for project-based requirements.

Get Ledger Blade Price & Availability

📞 Call / WhatsApp: +91 98888 82322

📧 Email: amcosales1@gmail.com

🌐 Website: www.amcoexports.com

Pan-India supply | Export orders supported | Manufacturer pricing

Stay Connected

Instagram: https://www.instagram.com/amcoexports

LinkedIn: https://www.linkedin.com/in/amcoexports

Scaffolding Blade – FAQ

Q1: What sizes/weights are available in Ledger Blades?

A: 150g, 160g, 170g, 200g, and 250g.

Q2: What materials are used?

A: High-grade steel forged through a hot drop forging process.

Q3: Are these compatible with all Cuplock systems?

A: Yes, they fit all standard Cuplock ledgers and verticals.

Q4: Why choose drop forged ledger blades?

A: They offer superior strength, better impact resistance, and longer life than casted or fabricated versions.

Q5: Do you export these scaffolding components internationally?

A: Yes, we are specialized Drop Forged Ledger Blade Manufacturers and Scaffolding Fasteners Suppliers from India, exporting high-quality construction components worldwide.