What Is a Scaffolding Toggle Pin?

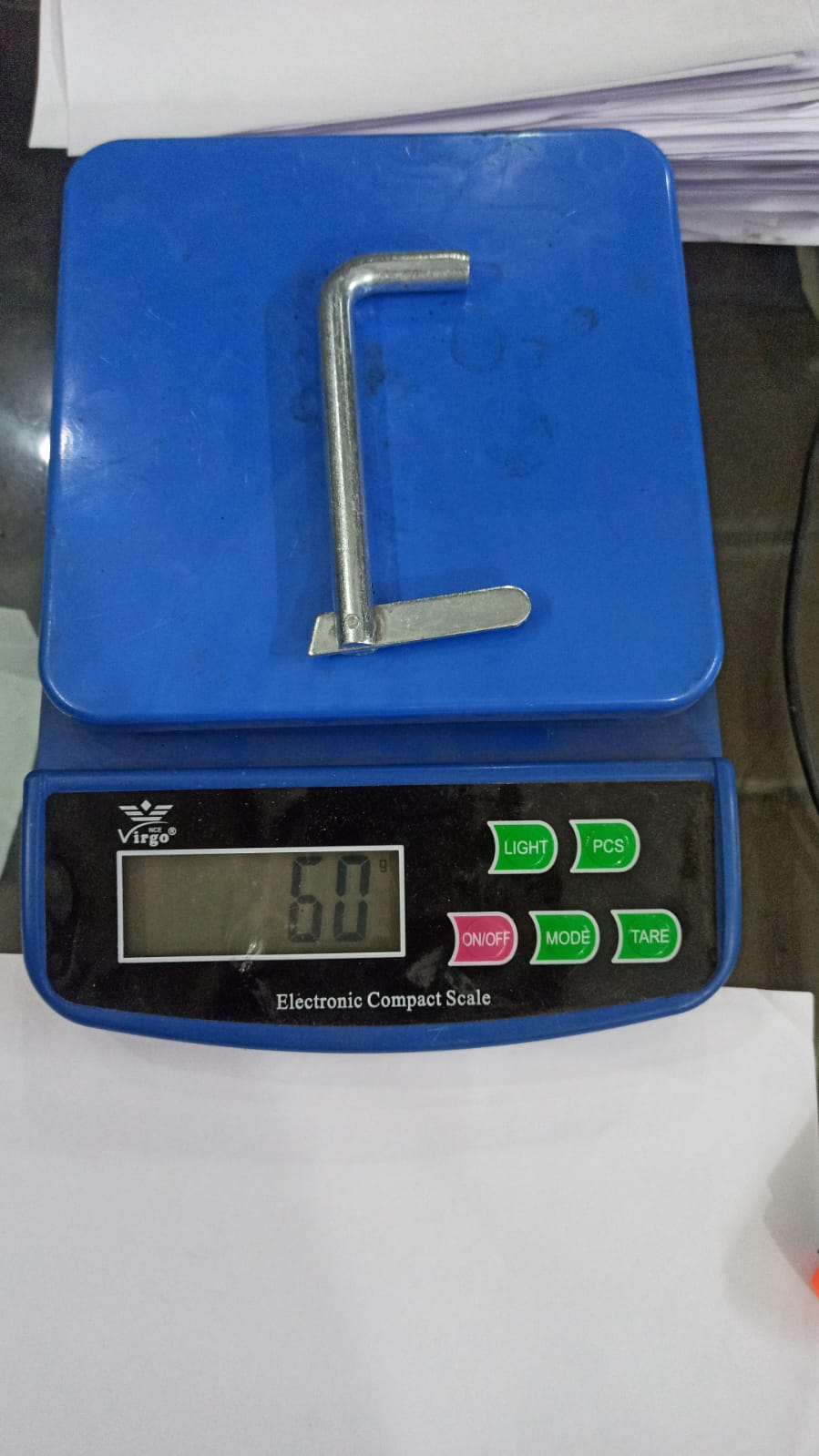

A Scaffolding Toggle Pin is a gravity-based drop-in locking pin used in frame scaffolding systems. It features an L-shaped steel body with a pivoting flat locking plate that automatically drops into position once inserted through aligned scaffold holes.

Because the locking mechanism works on gravity, it eliminates the need for bolts, nuts, or tightening tools. This allows faster assembly and dismantling, improving efficiency and reducing labor time on construction sites.

Where Contractors Use Toggle Pins

Contractors install gravity pins at key connection points within frame scaffolding systems. These points include frame-to-frame joints, vertical posts connected to base plates, and caster wheel stems in mobile scaffolds.

In addition, maintenance teams use gravity pins in access towers and temporary platforms. These applications demand quick locking without compromising safety.

Technical Specifications of Toggle Pin

| Parameter | Specification |

|---|---|

| Product Name | Scaffolding Gravity Pin |

| Also Known As | L-Shape Toggle Pin, Frame Gravity Pin, Lock Pin |

| Product Category | Scaffolding Accessories |

| Application | Frame scaffolding systems |

| Base Material | Mild Steel |

| Surface Finish | Galvanized / Zinc Plated |

| Design Type | L-shape with pivoting flat locking plate |

| Locking Mechanism | Gravity-operated self-locking |

| Installation Method | Tool-free, drop-in type |

| Removal Method | Manual lift and pull |

| Nominal Weight | ~60 grams (actual) |

| Weight Consistency | Controlled for batch uniformity |

| Corrosion Resistance | Suitable for outdoor site conditions |

| Vibration Resistance | High (gravity lock prevents lift-out) |

| Reusability | Designed for repeated site use |

| Manufacturing Process | Precision fabrication |

| Edge Finish | Smooth, burr-free, site-safe |

| Compatibility | Frame scaffolding, verticals, base plates, casters |

| Usage Environment | Construction, industrial & infrastructure sites |

| Country of Origin | India |

| Supply Type | Manufacturer direct |

| Order Type | Bulk & project-based supply |

Why Contractors Prefer Our Toggle Pins

Tool-Free Installation

Workers insert the pin by hand and complete the connection in seconds. Consequently, teams reduce labour time during erection and dismantling.

toggle -Based Auto Locking

The locking plate drops automatically after insertion. Therefore, the pin stays secure even under vibration and movement.

Optimized Weight (~60 g)

This gravity pin uses a controlled weight that balances strength and ease of handling. Instead of adding unnecessary bulk, the design supports efficient site work.

Scaffolding-Specific Design

Manufacturers design this pin specifically for frame scaffolding systems. As a result, the pin fits consistently and performs predictably across batches.

How the Toggle Pin Works

First, the installer aligns the scaffold components at the connection point.

Next, the installer inserts the gravity pin through the aligned holes.

Then, the flat locking plate drops under gravity and locks the pin.

As a result, the connection remains secure without additional fastening.

No tightening is required.

>No torque control is needed.

>No tools are involved.

Applications of toggle pin in Construction and Infrastructure Projects

Construction teams use scaffolding gravity pins in commercial buildings, industrial plants, and infrastructure projects. Moreover, rental scaffolding companies rely on these pins because crews assemble and dismantle systems repeatedly.

Because gravity pins maintain reliable locking, formwork and access-solution providers also use them in temporary support structures.

Manufacturing Quality and Control

As a manufacturer-direct product, this gravity pin follows strict production controls. The manufacturing process maintains consistent weight, uniform dimensions, and smooth edges.

In addition, quality checks ensure reliable locking action and long service life under normal site conditions. These controls help contractors maintain predictable performance throughout a project.

Why Buy Scaffolding Gravity Pins Direct from the Manufacturer

Direct purchasing eliminates trader-level inconsistencies. Furthermore, it ensures controlled specifications, stable pricing for bulk orders, and dependable supply schedules.

For EPC contractors and infrastructure buyers, manufacturer-direct sourcing also simplifies quality approval and procurement planning.

Toggle pin -Who Uses This Product

Scaffolding contractors, EPC companies, and industrial maintenance teams use gravity pins daily. Likewise, rental scaffolding providers and formwork suppliers depend on these pins for fast and secure frame connections.

Order & Enquiry

For bulk orders, project pricing, or technical support:

📞 +91 98888 82322

🌐 www.amcoexports.com

PAN-India supply available for commercial and infrastructure projects.

Explore our range of high-strength pins for scaffolding systems, including toggle pins, gravity pins, and safety locking pins for secure connections and fast assembly.

Follow us on Instagram :

https://www.instagram.com/amcoexports

Follow us on LinkedIn :

https://www.linkedin.com/in/amcoexports/

Frequently Asked Questions (FAQs)

Q1: What material is the scaffolding toggle pin made from?

A: Manufactured from galvanized steel for corrosion resistance and long site durability.

Q2: Is this toggle pin suitable for frame scaffolding systems?

A: Yes, designed for secure locking in frame scaffolding structures with tool-free installation.