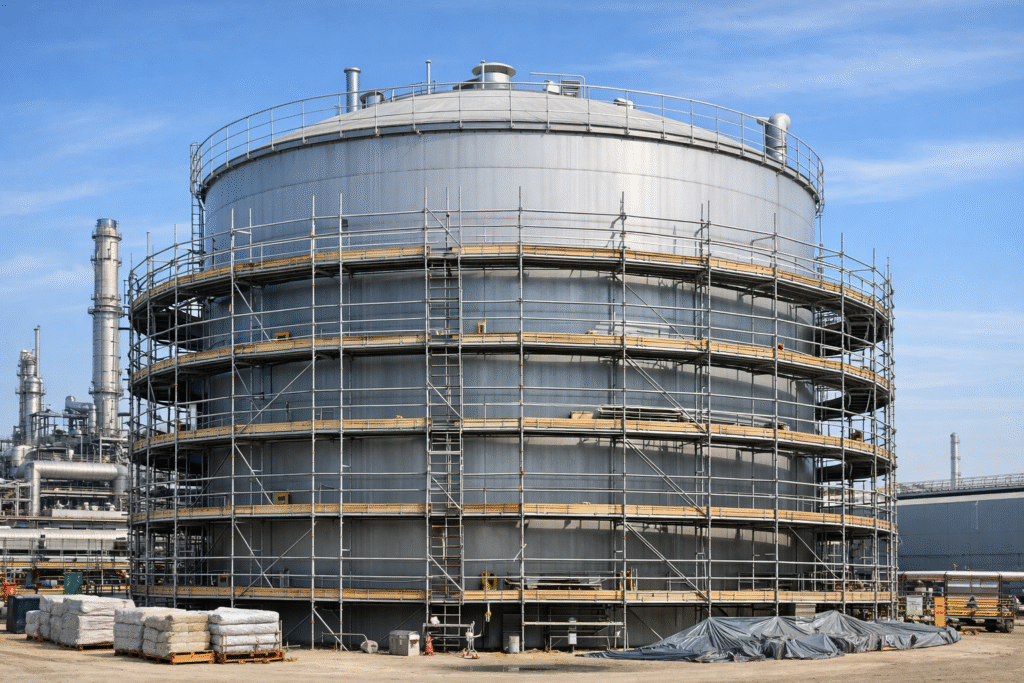

Tank insulation and industrial maintenance work cannot be executed safely or efficiently without proper access systems. Whether it’s a crude oil storage tank at a refinery, a chemical processing vessel, or a utility tank in a power plant, insulation contractors depend on reliable scaffolding material supply for tank insulation and industrial maintenance to complete work on schedule and without safety compromise.

At AMCO Exports, we support insulation contractors, EPC companies, and industrial maintenance teams as a dedicated industrial scaffolding material supplier, providing access components designed specifically for circular tank structures and outdoor operating conditions across India.

This guide explains why scaffolding is essential for tank insulation, the real challenges faced on-site, and how choosing the right material supplier directly impacts safety, cost, and productivity.

Why Industrial Tanks Require Dedicated Scaffolding Systems

Industrial tanks are not simple vertical surfaces. Insulation work involves curved profiles, varying diameters, and continuous elevation changes — often with workers operating at height for extended durations.

For insulation contractors, scaffolding enables:

- Safe access around the entire tank circumference

- Stable working platforms for insulation fixing and cladding

- Adjustable height control as work progresses upward

- Secure mounting points for guardrails and safety systems

Without properly planned access, insulation work slows down, safety risks increase, and labor productivity drops sharply.

This is where tank insulation scaffolding support cost becomes critical — poorly selected materials quickly lead to delays and rework.

Why Industrial Tanks Require Dedicated Scaffolding Systems

Industrial tanks are not simple vertical surfaces. Insulation work involves curved profiles, varying diameters, and continuous elevation changes often with workers operating at height for extended durations.

For insulation contractors, scaffolding enables:

- Safe access around the entire tank circumference

- Stable working platforms for insulation fixing and cladding

- Adjustable height control as work progresses upward

- Secure mounting points for guardrails and safety systems

Without properly planned access, insulation work slows down, safety risks increase, and labor productivity drops sharply.

This is where tank insulation scaffolding support cost becomes critical poorly selected materials quickly lead to delays and rework.

Access Challenges in Tank Insulation & Industrial Maintenance

Tank insulation sites bring unique operational challenges that standard construction scaffolding cannot handle efficiently.

Curved Tank Geometry

Straight scaffold layouts do not naturally follow circular surfaces. Improvised connections create gaps, instability, and unsafe platforms.

Continuous Height Adjustment

Insulation is carried out in phases. Platforms must adapt as work moves vertically without dismantling the entire structure.

Outdoor & Industrial Exposure

Most tank insulation happens outdoors exposed to heat, rain, chemicals, and coastal conditions.

Safety Compliance

Industrial sites demand proper guardrails, toe boards, and load-rated fittings at every working level.

To overcome these challenges, insulation contractors rely on specialized scaffolding accessories, not generic building materials.

Scaffolding Materials Used for Tank Insulation Projects

AMCO Exports focuses on supplying industrial-grade materials used by insulation and maintenance contractors nationwide.

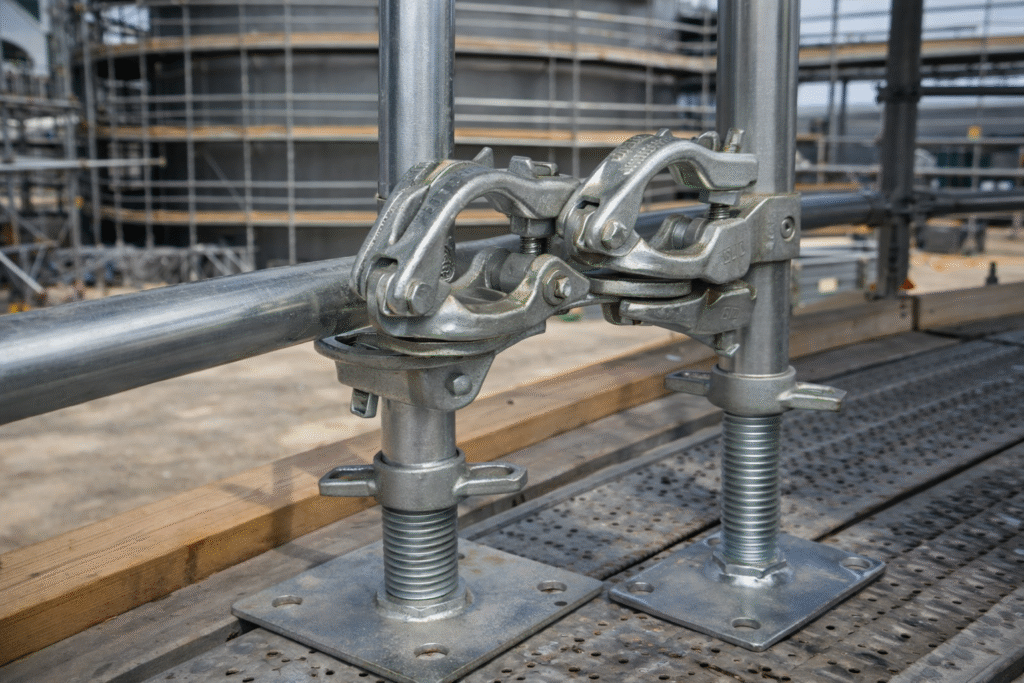

Swivel Couplers for Circular Tank Scaffolding

Swivel couplers allow pipes to connect at variable angles, making them essential for following the curved profile of tanks.

They are commonly used for:

- Circular bracing

- Diagonal reinforcement

- Continuous working platforms around tanks

Double Couplers for Structural Stability

Double couplers provide rigid 90-degree connections, forming the load-bearing framework of tank access scaffolding.

Base Jacks for Level Control in Industrial Yards

Uneven yard surfaces are common around tanks. Adjustable base jacks ensure level platforms and proper load transfer.

Guardrail & Safety Fittings for Maintenance Work

Guardrails and safety fittings are mandatory where insulation teams spend long hours working at height.

The right combination of these components plays a major role in controlling industrial maintenance scaffolding support cost over the project lifecycle.

Outdoor Durability Requirements for Tank Insulation Scaffolding

Tank insulation scaffolding is continuously exposed to:

- Weather fluctuations

- Chemical vapors

- Moisture and heat

This is why insulation contractors prefer galvanized components with clean threading and consistent material strength. Low-quality fittings corrode quickly, increasing replacement frequency and overall cost.

AMCO Exports supplies scaffolding materials engineered for repeat industrial use and long-term outdoor durability.

Case Study: Tank Insulation Scaffolding Supply – Western India

An insulation contractor working at a petroleum storage terminal in Western India approached AMCO Exports during a large-diameter tank insulation project.

Project Challenges

- Circular tank access at multiple elevations

- Tight shutdown timelines

- Outdoor coastal exposure

- Strict industrial safety norms

AMCO Exports Supply Scope

We supplied:

- Swivel and double couplers

- Scaffold tubes and ledgers

- Adjustable base jacks

- Guardrail fittings and hardware

Outcome

- Stable circular access platforms achieved

- Insulation work progressed without access delays

- Reduced corrosion-related material failure

- Project completed within the shutdown window

The contractor continues sourcing tank insulation scaffolding materials from AMCO Exports for ongoing industrial maintenance projects.

Cost Factors in Tank Insulation Scaffolding Support

The overall cost of scaffolding support for tank insulation depends on:

- Tank diameter and height

- Number of working levels required

- Type of couplers and safety fittings used

- Duration of insulation work

Selecting the correct accessories from the start significantly reduces rework, downtime, and material replacement costs.

Why Industrial Contractors Choose AMCO Exports

AMCO Exports operates strictly as a material supply partner, not a contractor. We understand insulation workflows and supply materials accordingly.

We offer:

- Bulk industrial material availability

- Consistent sizing and quality

- Fast dispatch across India

- Products suited for heavy-duty industrial environments

Important Notice:

AMCO Exports supplies scaffolding and formwork material only. We do not undertake turnkey installation or insulation services.

This ensures clear scope definition and avoids execution-related delays.

Get Scaffolding Material Supply Support

If you are searching for:

- Scaffolding material supply for tank insulation

- Industrial maintenance scaffolding accessories

- A reliable industrial scaffolding supplier

AMCO Exports is ready to support your project.

📞 Call: +91 98888 82322

🌐 Website: www.amcoexports.com

Share your tank details and access requirements — our team will help you plan the right material supply.

Stay Connected

Instagram: https://www.instagram.com/amcoexports/

LinkedIn: https://www.linkedin.com/in/amcoexports/

tank access scaffolding – Frequently Asked Questions

Do you supply industrial tank scaffolding systems materials only?

Yes. AMCO Exports supplies industrial tank scaffolding systems materials and accessories only. We do not provide erection, insulation, or turnkey services. Installation is handled by specialist contractors.

Which scaffolding accessories are commonly used for tank insulation work?

industrial tank scaffolding systems typically uses swivel couplers for curved profiles, double couplers for structural strength, adjustable base jacks for level control, and guardrail fittings for worker safety.

Are your scaffolding materials suitable for circular tanks?

Yes. Our industrial tank scaffolding systems accessories are widely used for circular tanks, storage vessels, and industrial process equipment requiring curved access platforms.

Can AMCO Exports handle urgent or bulk tank insulation scaffolding supply?

Yes. We regularly support urgent shutdowns and bulk supply requirements for tank insulation scaffolding across refineries, power plants, and industrial maintenance sites in India.

How do I get pricing for tank insulation scaffolding materials?

Share your tank diameter, height, quantities, and project location with our sales team. We will provide a quotation based on your tank insulation scaffolding material requirements.