Forged scaffold stronger? This is one of the most common questions contractors ask before buying couplers. In this blog, we compare pressed steel vs drop forged scaffolding couplers based on strength, durability, load performance, and the best use for construction projects.

✅ Is pressed steel or forged scaffold stronger?

Let’s break it down in a simple way so you can pick the right coupler for your site without confusion.

Why This Comparison Matters on Real Construction Sites

Scaffolding couplers do one important job: they hold scaffold tubes tightly together.

So if the coupler fails, the scaffold connection weakens. As a result, you may face:

- loosening joints

- tube slippage

- misalignment

- safety risks during load

That’s why understanding is pressed steel or forged scaffold stronger helps you avoid future problems.

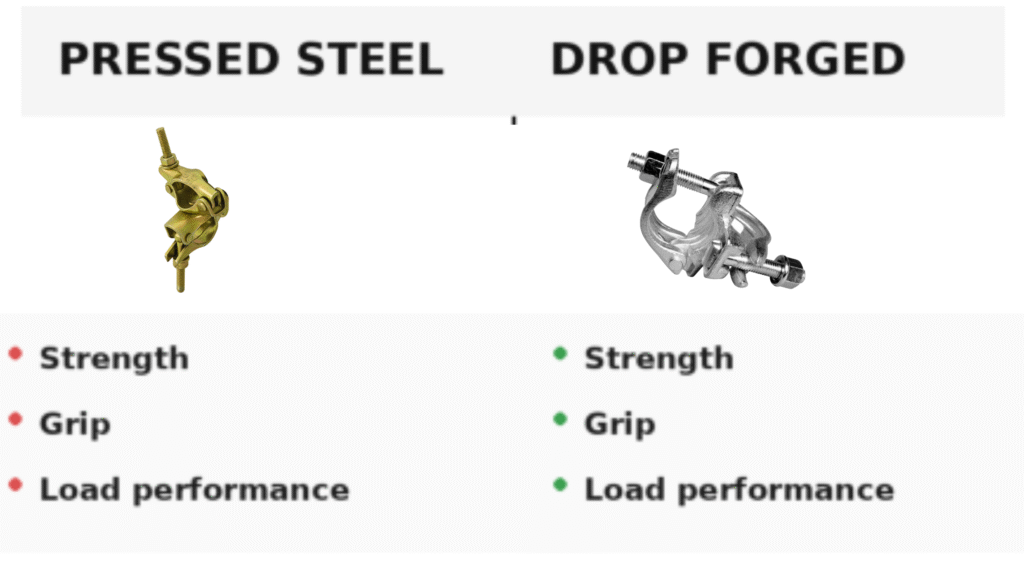

What is a Pressed Steel Scaffolding Coupler?

A pressed steel coupler is manufactured by stamping and pressing steel sheets into shape. Because of this manufacturing method, it works well for light-duty scaffolding.

Key features of pressed couplers:

- made from steel sheet pressing

- lightweight design

- affordable

- suitable for low-load scaffolding

In other words, contractors often choose pressed couplers when the project is short-term and budget is the priority.

What is a Drop Forged Scaffolding Coupler?

A drop forged scaffolding coupler is made by heating steel and shaping it under high pressure using forging dies. Therefore, the coupler body becomes denser, tougher, and stronger.

Key features of drop forged couplers:

- stronger internal metal structure

- better load performance

- higher impact resistance

- longer service life

That’s why, when someone asks is pressed steel or forged scaffold stronger, the answer mostly points to drop forged couplers.

Explore our full range of scaffolding couplers here

For heavy-duty connections, check our drop forged swivel coupler

You can also compare with our right angle coupler (double coupler)

For tube-to-tube joining, see our sleeve coupler.

Need system scaffolding? View our cuplock scaffolding accessories.

For pricing and bulk orders, contact AMCO Exports today

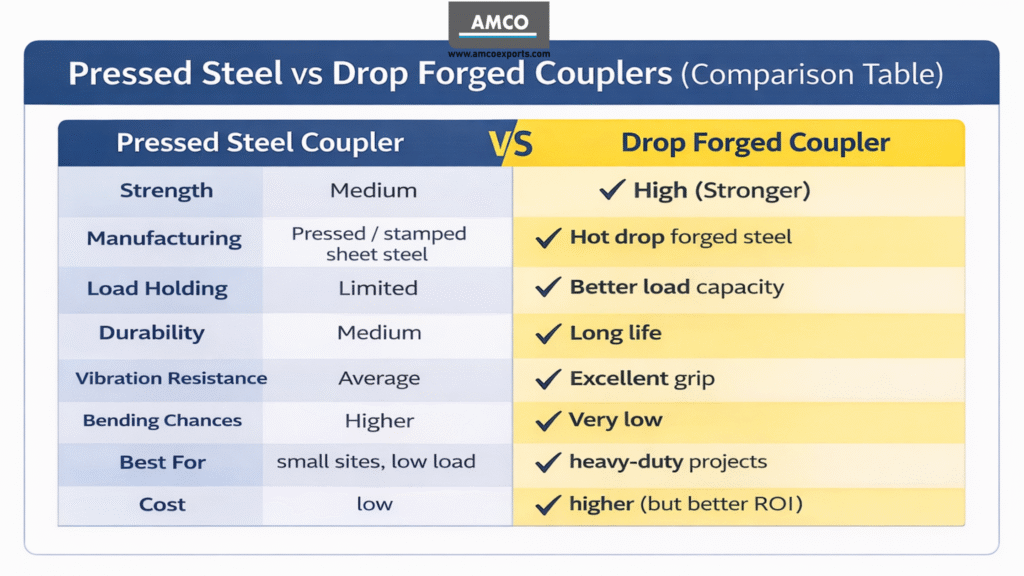

✅ Pressed Steel vs Forged Coupler

Is Pressed Steel or Forged Scaffold Stronger?

Here’s the clear answer:

✅ Drop forged scaffolding couplers are stronger than pressed steel couplers.

Moreover, drop forged couplers perform better under:

- heavy load

- vibration

- repeated tightening

- long-duration scaffolding

So if your project involves safety and stability, forged couplers become the smarter choice.

Which Coupler Should You Choose?

✅ Choose Pressed Steel Couplers if:

- your scaffold load stays light

- project duration is short

- budget is tight

- scaffolding remains in simple structure

However, you should avoid pressed couplers for heavy load areas.

✅ Choose Drop Forged Couplers if:

- your project is high-rise

- safety is critical

- scaffold stays for long period

- you want long life with fewer failures

Therefore, drop forged couplers work best for contractors who want stability and peace of mind.

Why Couplers Get Loose on Site

Most contractors face this problem:

“Coupler loose ho gaya.”

This happens when:

- thread quality is not accurate

- bolt grade is weak

- coupler body bends over time

- rust reduces grip

Pressed couplers loosen faster. On the other hand, drop forged couplers maintain tight grip for longer.

That’s also why people keep searching:

✅ is pressed steel or forged scaffold stronger

Long-Term Cost: Which One Saves Money?

At first, pressed couplers look cheaper. However, replacements and failures increase cost later.

Pressed steel couplers:

✅ low initial cost

❌ more replacement

❌ more loosening

❌ shorter lifespan

Drop forged couplers:

✅ high strength

✅ longer usage

✅ stable grip

✅ fewer replacements

As a result, drop forged couplers provide better ROI for serious projects.

Explore our full range of scaffolding couplers here

For heavy-duty connections, check our drop forged swivel coupler

You can also compare with our right angle coupler (double coupler)

For tube-to-tube joining, see our sleeve coupler.

Need system scaffolding? View our cuplock scaffolding accessories.

For pricing and bulk orders, contact AMCO Exports today

✅ Buy Drop Forged / Pressed Couplers Direct from Manufacturer – AMCO Exports

At AMCO Exports (Jalandhar), we manufacture and supply:

- ✅ Drop Forged Couplers

- ✅ Pressed Steel Couplers

- ✅ Swivel Coupler / Double Coupler

- ✅ Sleeve Coupler / Putlog Coupler

- ✅ Base Jack / U-Head Jack

- ✅ Cuplock & scaffolding accessories

Moreover, we supply:

✅ bulk packing

✅ pan-India dispatch

✅ export-ready packing

📌 Get Today’s Best Coupler Quote

Want bulk pricing for couplers?

📞 Call / WhatsApp: +91 98888 82322

📧 amcosales1@gmail.com

🌐 www.amcoexports.com

👉 Message: “Coupler Quote”

and we’ll send:

✅ price list

✅ product photos

✅ packing details

✅ dispatch timeline

Follow us on LinkedIn: https://www.linkedin.com/in/amcoexports/

Follow us on Instagram: https://www.instagram.com/amcoexports/

Frequently Asked Questions (FAQ)

1) Is pressed steel or drop forged scaffolding coupler stronger?

Drop forged scaffolding couplers are stronger than pressed steel couplers. Forging makes the metal structure denser and tougher, so it performs better under heavy load, vibration, and repeated tightening. That’s why forged couplers are preferred for high-risk construction projects.

2) Which coupler is best for heavy-duty scaffolding projects—pressed or drop forged?

For heavy-duty scaffolding, drop forged couplers are the best choice. They provide higher load capacity, better grip strength, and longer service life. Pressed couplers may work in light load setups, but forged couplers are safer for long-term and high-rise scaffolding.

3) When should contractors use pressed steel scaffolding couplers?

Contractors should use pressed steel couplers for light-duty scaffolding like short-term work, small buildings, painting, plastering, or low-height structures. They are budget-friendly and lightweight, but they should be avoided in high-load or safety-critical scaffolding areas.

4) Why do pressed steel couplers loosen faster on construction sites?

Pressed couplers loosen faster because their body can deform slightly over time, especially under load and vibration. Also, low-grade bolts, inaccurate threading, and rust reduce the grip. In comparison, drop forged couplers hold tighter for longer and handle repeated tightening better.

5) Are drop forged scaffolding couplers worth the higher price for long-term use?

Yes, drop forged couplers are worth the price because they last longer and reduce replacements. They maintain tight grip, resist bending, and perform better in long-term scaffolding use. Over time, forged couplers provide better ROI and improve on-site safety.